cucchi spa

SECOND HAND MACHINE TOOLS: high-quality at competitive prices constantly in stock.

Second-hand machine tools

Cucchi S.p.A since1948 has specialized in the overhauling and sale of second-hand machine tools. In a short time the company became market leader in the metal working sector (metal removal as well).

Sale in stock.

Maintenance and repair.

High-quality, readily available spare parts.

One of most well-stocked warehouses in Italy and one of the most important in EUROPE for Gear machines which offers a wide range of machine tools manufactured by some of the most important European and American manufacturers. Machineries for gear processing, as well as other details of medium and large series, are always in stock

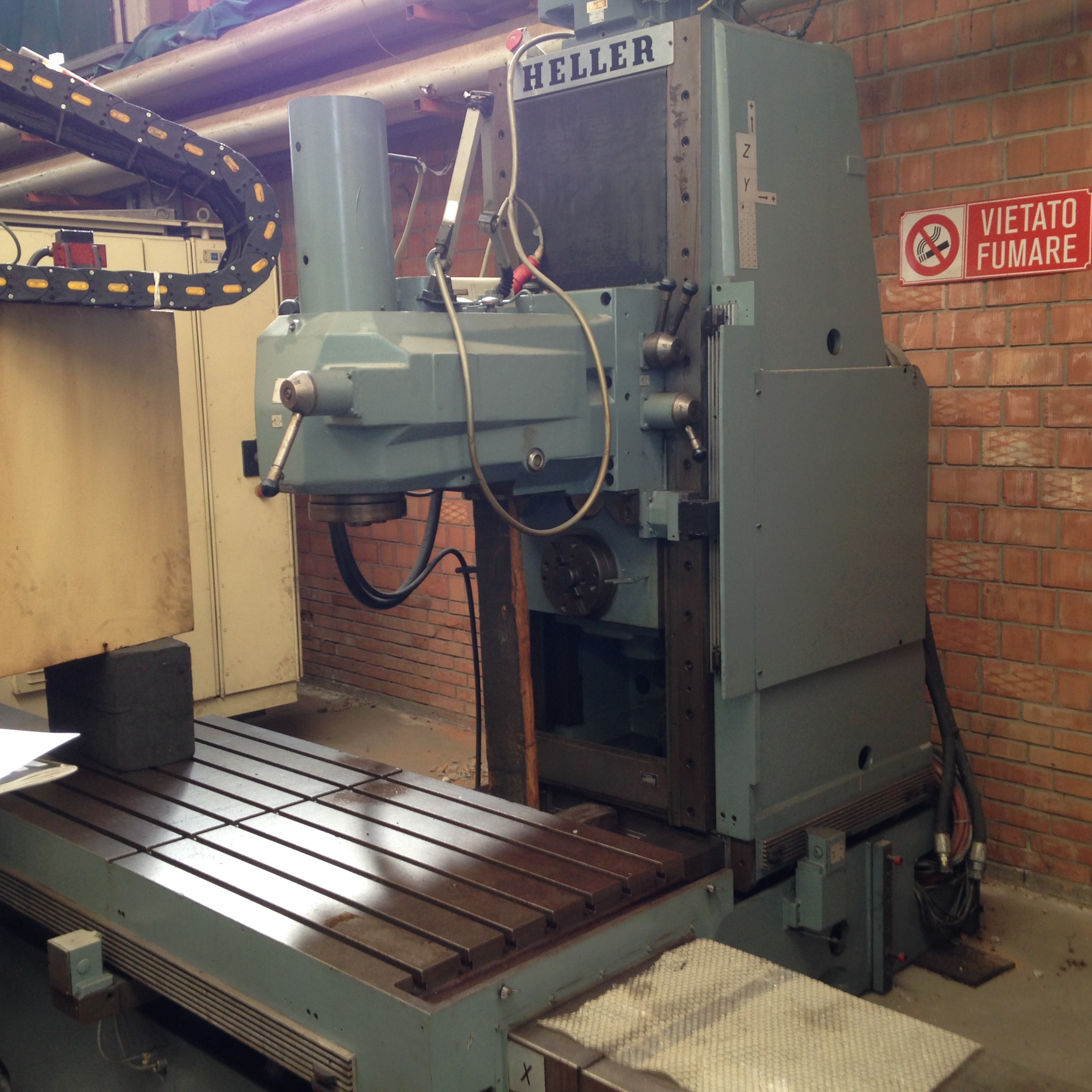

Machine tools in the showcase

Our machine tools

Cucchi S.p.A provides one the widest range of second-hand machine tools in Europe.

Of particular note are Cucchi’s excellent second-hand machine tools for gears, overhauled and/or retrofitted by our main suppliers.

Our brands

Videos of some Machinery

Frequently Asked Questions FAQ

What are the conventional machine tools?

Conventional machine tools are machines that use conventional methods and traditional techniques to perform machining operations on materials. Below I list some of the most common conventional machine tools:

- Lathe: a machine that rotates the workpiece and uses tooling cutting tools to remove excess material and create shapes and precise surfaces.

- Cutter: a machine that uses a rotary cutter to cut material and create complex shapes. It can be used to create grooves, flat surface milling and contour profiling.

- Drill: a machine that uses a rotary drill bit to make holes in material. It can be used to drill metals, wood and plastics.

- Sawing machine: a machine used to cut material into smaller pieces. Sawing machines can be manual or automatically controlled.

- Grinder: a machine that uses a rotating abrasive wheel to remove excess material or to refine surfaces.

- Boring machine: a machine that uses a rotary cutter to create precise, finished holes in large parts.

- Press: a machine that uses compressive force to deform or form material. It can be used to fold, shape and print material.

- Shearer: a machine that uses sharp blades to cut material into sheets or smaller pieces.

- Cylindrical grinder: a machine used to grind the outer surface of a cylindrical object to make it smooth and precise.

These are just some of the most common conventional machine tools common, but there are many other variations and subcategories of machine tools used in various industries.

What are machine tools at a glance?

Machine tools at a glance are a set of machines that use sharp tools to remove excess material and create precise shapes, surfaces and holes in materials such as metals, wood, plastics and others. These machines are widely used in the manufacturing industry for the production of a wide range of components and parts.

Machine tools at a glance include various types, such as lathes, milling machines, drills, saws, boring machines, grinders and many others. Each machine tool has a specific function and can be used to perform specific machining operations. For example, a lathe is used for machining parts that are cylindrical and rotating, while a milling machine is used to create complex shapes and flat surfaces.

The goal of machine tools in brief is to achieve precise and repeatable processing of materials, ensuring high standards of quality and precision in manufacturing operations. Often, modern machine tools are equipped with computerized numerical control (CNC) systems, which allow programming of operations and automation of machining processes.

In summary, machine tools are fundamental devices in the manufacturing industry that enable the efficient and precision of components and parts through the use of sharp tools and a variety of machining operations.

What is meant by machine tools?

Machine tools are mechanical devices used to machine materials such as metals, wood, plastics and others to create precise shapes, surfaces, holes and finishes. These machines are crucial in the manufacturing industry and play a key role in the production of a wide range of products.

Machine tools enable machining operations such as cutting, drilling, milling, turning, grinding, shaping, forming and many others. They use sharp or abrasive tools to remove the material in excess and shape the workpiece to the required specifications.

Machine tools are designed to be precise, repeatable, and robust. They can be controlled manually by the operator or be equipped with computerized numerical control (CNC) systems for the automation and programming of machining operations.

Machine tools are widely used in a variety of industries, including the automotive industry, aerospace, tool manufacturing, the energy industry, the electronics industry, and many other manufacturing sectors. They are essential for the production of components and parts that require high precision and accurate machining.

How do CNC machines work?

Computer numerical control (CNC) machine tools are machines that use a computer control system to automate and control the machining process. This system allows machining operations to be programmed and executed precisely and repeatably. Here is a summary of how CNC machines work:

-

Programming: The operator or programmer creates a CNC program specifying the necessary machining instructions. This is usually done using a CNC programming language, such as the G-code language, which describes tool movements and actions.

-

Workpiece preparation: The workpiece is fixed in the machine tool stably and securely. The reference positions and tools required for the machining operation are also set.

-

Start of machining cycle: The operator starts the CNC program on the machine. The numerical control system interprets program instructions and transforms the information into tool and workpiece movements.

-

Axis movements: The CNC machine tool has motion axes (usually three or more) that control the position of the tool relative to the workpiece. Axis motors move according to CNC program instructions to position the tool correctly.

-

Workpiece machining: The tool, such as a milling cutter or lathe, moves according to CNC program commands to remove excess material and create the desired shape or surface on the workpiece. The operator can monitor the process and make any necessary adjustments.

-

Precision control: The CNC machine tool is equipped with sensors and measuring devices to control the precision of machining operations. These sensors can detect position, speed and other crucial information to ensure accurate results.

-

End of machining cycle: Once the machining operation is completed, the CNC machine tool stops and the operator can remove the workpiece.

CNC machine tools offer many advantages, including greater accuracy, faster machining speed, higher productivity, and the ability to perform complex and detailed operations automatically. This computerized control system has revolutionized the manufacturing industry, enabling greater efficiency and quality in the production of components and parts.